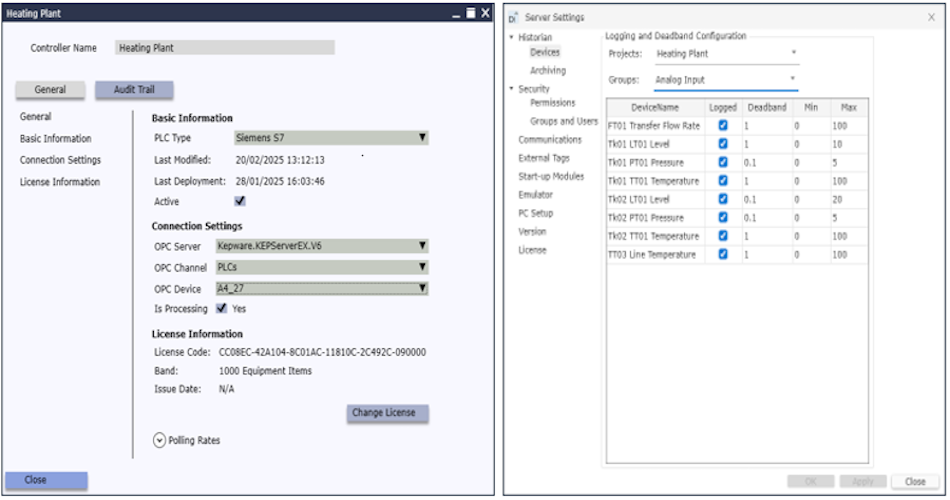

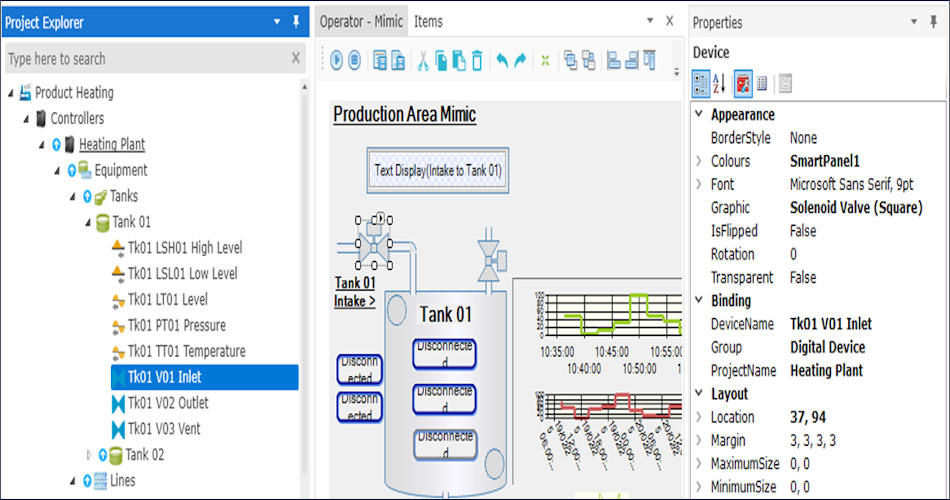

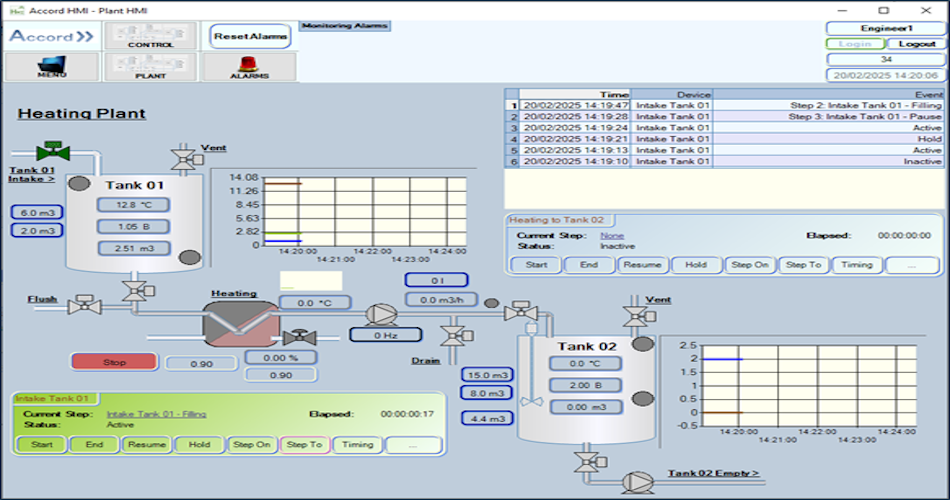

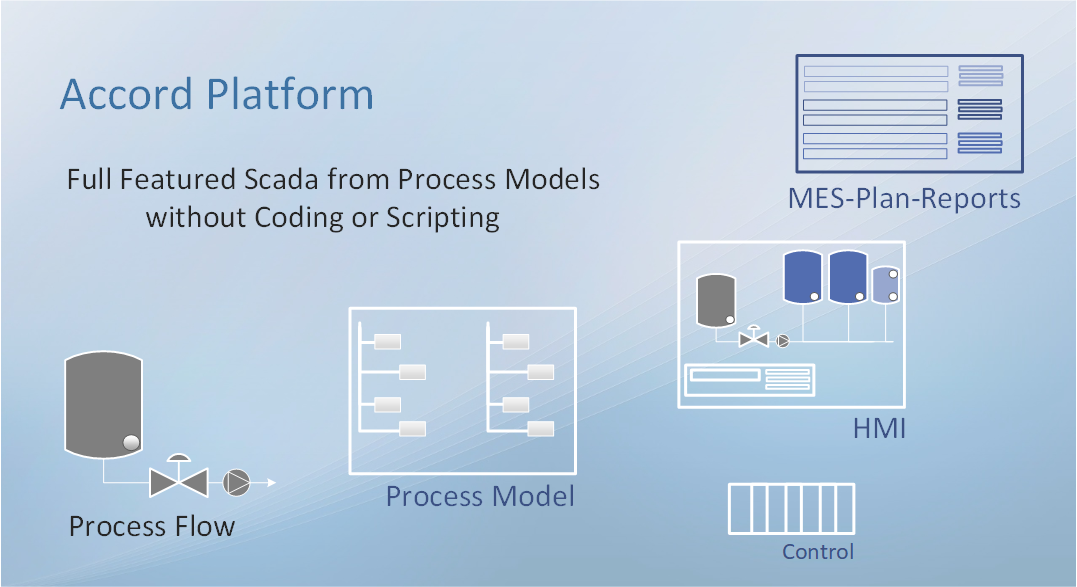

Accord provides fully integrated systems by being object-oriented, list based and described by data instead of code. Designed to unify logic, visualization, and reuse, Accord helps engineers deliver higher performance systems with fewer integration points and less lifecycle complexity.

Accord allows engineers to implement solutions very efficiently, providing large reductions in time for control development, visualisation development, documentation and commissioning.

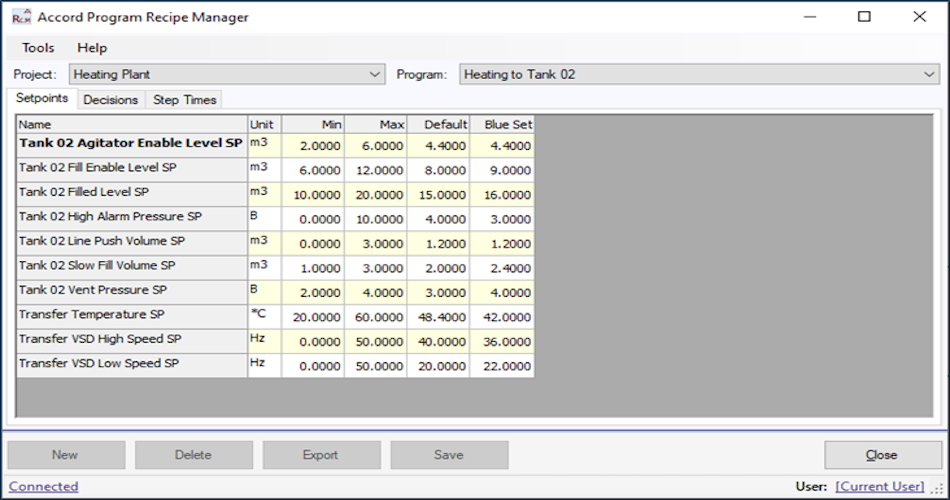

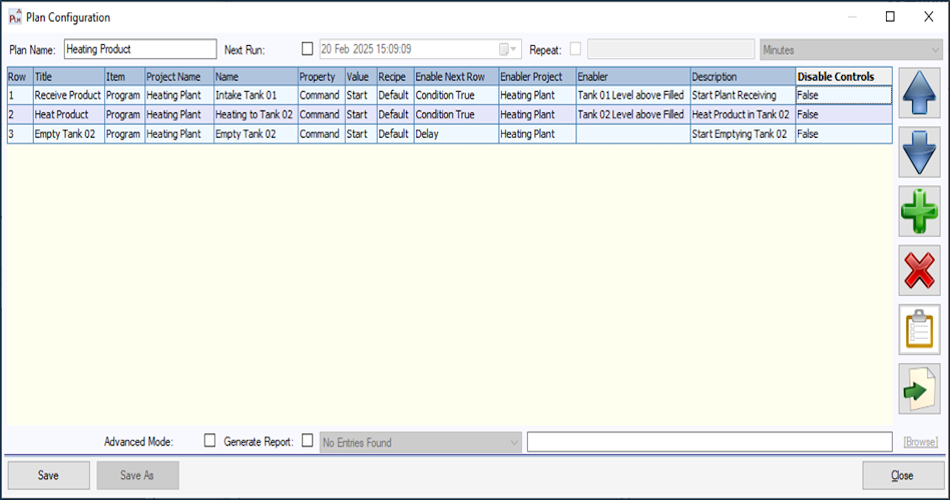

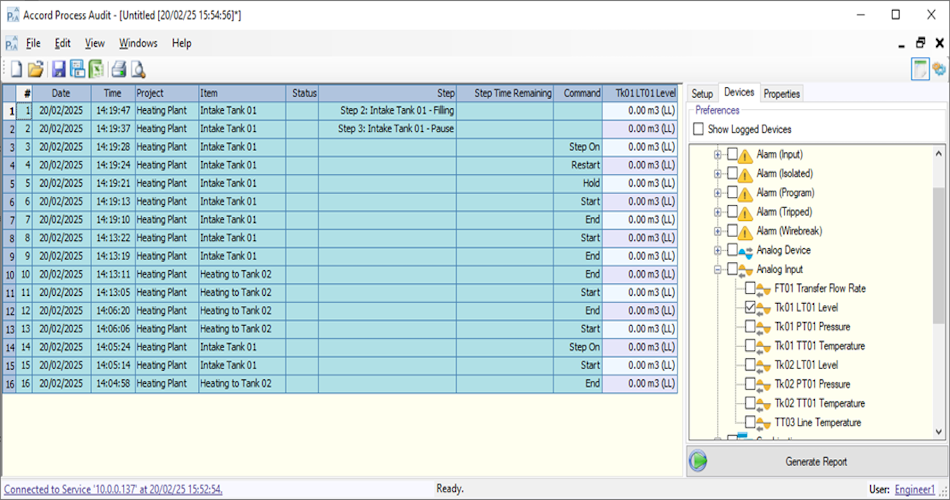

Accord contains modules for Control, HMI, Reporting, Recipe Management and MES Functions and so can provide a comprehensive Scada solution for any process plant.

Quick Introduction Flow examples – please use the arrows ->

Accord is deployed and used every day to provide safe control for many types of Process, including

| Chemical Blending Process | Pharmaceutical Gel and Lotion Manufacture |

| Pharmaceutical Purified Water | Pharmaceutical Media Preparation and Storage |

| Food and Beverage CIP | Food and Beverage Production |

| Chemical Bulk Storage Tanks | Utilities |

Many important plants chose Accord for its dependability. It is used as the production system in the largest bottled water plant, largest biogas plant, largest bulk chemical production plant, and largest metal smelter plant in Ireland and is in use in plants in Germany, China and Middle East.